Your new chesterfield sofa or club chair will begin to take shape when it leaves our padding department, for it is here that the piece begins to take on its distinctive shape. Springs are added to the frame in the form of individual coil springs, or serpentine springs carefully and painstakingly fitted prior to the padding to ensure the lasting shape achieved by our craftsmen.

The visual and all important final stage in the production of your fully hand made product is the application of the best selected fine grain hides in the finish that you have selected. This process can take up to three days to complete, depending upon the complexity of the model you have chosen. Finally the chesterfield sofa or club chair is finished with the application of the buttons and studding. Unlike many other manufacturers, here at Distinctive Chesterfields, we continue to use traditional methods and fit individual studs to each piece of furniture, with up to 1200 per item dependant on type.

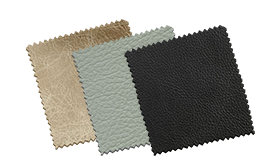

All leather chesterfields and our sought after club chairs are, as can be seen, made to the highest standards, using the finest materials assembled and finished by the best craftsmen in the furniture trade. We will supply you from a range of style and colour finishes, or you can request a sofa or chair, lower, higher or deeper, with a firm or soft feel. In fact, we will be happy to quote for any special requirement you may have.